RNNR Committee Report

If you have any questions or comments regarding the accessibility of this publication, please contact us at accessible@parl.gc.ca.

Economic Recovery in Canada’s Forestry Sector: Green and Inclusive

Introduction

In October 2020, the House of Commons Standing Committee on Natural Resources (the committee) decided to undertake a study of Canada’s forestry sector with a goal to make recommendations to the Government of Canada regarding ways to support economic recovery in the sector.

Over the course of 10 meetings, the committee heard from a wide range of experts about the challenges facing the forestry sector and potential solutions to maintain its economic vitality and long-term viability, notably by optimizing innovative uses for wood and taking advantage of the many environmental benefits provided by forests and forest products. The committee is pleased to present its final report, which summarizes the findings of its study and includes a series of recommendations to the Government of Canada.

The Benefits of Canada’s Forestry Sector

Forests are part of Canada’s natural and cultural heritage, particularly for Indigenous peoples and many rural communities across the country. As renewable resources, forests are known for their natural functions and environmental benefits. Forests are also an important component of Canada’s economy, for their recreational uses and for the many products that can be produced from them.

Canada’s forest area is 347 million hectares, making up 38% of the country’s total land mass and 9% of the world’s forests. Over half of this area (223 million hectares) has a long-term forest management plan (these areas are known as forest lands or managed forests). About 48% of Canada’s forests (168 million hectares) are certified for sustainable management by a third party. In 2019, the harvested area accounted for about 0.2% of the country’s total forest area (some 748,000 hectares).[1]

As shown in Figure 1, the forest industry is a source of employment and income for many Canadians across the country. In 2019, the forest industry directly employed 205,000 people in Canada and contributed $23.7 billion to its nominal gross domestic product. Many communities depend on the economic activity and jobs generated by the forest industry, especially rural and Indigenous communities. Indeed, the committee heard that about 600 communities across the country are closely tied to forests, and 300 of these depend on forest sector jobs as a partial or sole source of household income.[2] Over 70% of Indigenous people in Canada live in or close to forests. In 2016, Indigenous people held about 12,000 jobs in the industry, representing 7% of its labour force.[3]

Figure 1—Canada’s Forest Industry at a Glance

Source: Figure prepared by the Library of Parliament using data from NRCan, The State of Canada’s Forests—Annual Report 2020.

The forest industry has three main subsectors: forest operations, pulp and paper, and wood product manufacturing.[4] Each of these subsectors provides a range of products and services, as outlined in Figure 2. Forestry (or silviculture) and logging businesses carry out field operations and timber harvesting. The pulp and paper product manufacturing subsector includes businesses that make a wide range of products, from newsprint and printing and writing paper to packaging and hygiene products.[5] The wood products manufacturing subsector includes products of both primary manufacturing, such as lumber and structural panels, and secondary manufacturing, such as millwork and engineered wood products.[6]

In addition to conventional products, the committee found that value-added wood products are becoming increasingly varied and that multiple new products derived from forest biomass (known as biomaterials, bioproducts or bio-based products) are being marketed or under development.[7] These products make use of forest residues that would otherwise be considered waste. They include bioplastics, biochemicals, biofuels and bioenergy.

Figure 2—Types of Forest Products

Source: Figure prepared by the Library of Parliament.

In addition to their social and economic impacts, forest resources and the products made from them help create a low-carbon-emission economy. First, managed forests can serve as “carbon sinks,” meaning that they can sequester more carbon than they emit. However, this capacity may diminish when forests experience major natural disturbances such as climate change, insect pests, disease and forest fires, which can damage forest resources and may turn them into “carbon sources.”[8] Industrial forestry and human activities can also contribute to carbon emissions and impact biodiversity.[9]

As well, forest products and their associated value chain can support a circular bioeconomy that fosters optimal use of resources at every stage of the life cycle, reducing their environmental impact. Forest products are renewable and can replace non-renewable resources with a higher carbon footprint, such as synthetic or petrochemical products.[10] According to Natural Resources Canada, “Significant energy efficiency and emissions reduction technology have contributed to a 40% reduction in GHG (greenhouse gas) emissions from fossil fuels in the sector between 2007 and 2017.”[11] Witnesses cited the example of pulp and paper mills that have reduced their GHG emissions by approximately 70% since 1990, primarily by transitioning away from coal and other fossil fuels and in some cases opting for a cogeneration system that uses wood waste to generate electricity.[12]

Despite these important benefits, the forest industry faces numerous challenges. This report begins by outlining the key findings of this study, including the many economic and environmental challenges and the impact of the COVID‑19 pandemic on Canada’s forestry sector. The report also provides the Government of Canada with a policy path to maximize the forest industry’s potential, including leveraging the renewable and environmentally sustainable nature of wood products and optimizing the use of wood, increasing the supply of such forest products in the bioeconomy and diversifying markets.

Challenges to Canada’s Forestry Sector

Canada’s forestry sector has faced numerous economic and environmental challenges in recent years. The COVID‑19 pandemic has also affected the entire industry, disrupting operations and production capacity, but also opening up new opportunities. As a result, the testimony heard during this study shines a light on the current situation and the future potential of the forestry sector in Canada.

Lower Demand for Paper

A number of witnesses reported that global demand for paper continues to fall as digitization continues.[13] Natural Resources Canada found that demand for newsprint and printing and writing paper plunged by 13% and 6%, respectively, in 2019 relative to 2018.[14] In response to the decrease in demand, some facilities that make these products ceased operations, and businesses put investments to diversify their product offerings on hold.[15] These closures also hampered the conversion of plants that could transform paper or cellulose products into substitutes for other, higher-carbon-intensity products; these conversions would have required substantial investments.[16] This slowdown also hurt demand for lower-quality forest biomass, such as sawdust and sawmill residues, which is used by the pulp and paper industry.[17]

Trade Barriers

Protectionist trade policies cost and discriminate against the Canadian forest industry. Witnesses explained to the committee that the Canadian softwood lumber trade dispute—in which the United States (U.S.) has imposed countervailing and anti-dumping duties on imports of Canadian lumber—has cost Canadian forest companies just over $4 billion.[18] As Jean‑François Samray, President and Chief Executive Officer of the Quebec Forest Industry Council, pointed out, “This is money that cannot be used for modernization, the purchase of new equipment or the deployment of new technologies to make the Quebec and Canadian forest industry even more efficient.”

Canada is a major exporter of forest resources. In 2019, Canadian wood products exports were worth $36 billion. More than two thirds of Canada’s forest products are exported, most going to the U.S. (up to 68% in 2019).[19] Clearly, the American market is very important for Canadian wood products, but this fact makes Canada’s forest industry vulnerable to protectionist trade policies, such as those imposed during the softwood lumber trade dispute with the U.S. According to Jeff Bromley, Chair of the United Steelworkers Wood Council, this dispute has reduced U.S. market access for Canadian lumber by about 15% and caused extensive job loss, including nearly 11,000 lost jobs industry-wide since 2017.

Wood Fibre Supply

Stable, long-term supplies of wood fibre for industrial purposes are becoming more and more difficult to secure, in part because of natural disturbances. The committee heard that natural disturbances such as insect pests, disease and forest fires can reduce the quality and volume of wood available for commercial purposes.[20] Environmental changes can exacerbate these natural disturbances, which damage ecosystems and forest resources, compromising the sustainability of forestry.[21] As Derek Nighbor, President and Chief Executive Officer of the Forest Products Association of Canada (FPAC), explained, “Climate change has emerged as one of the most important transformational challenges, placing unprecedented pressure on our forests’ capacity to remain healthy and resilient.” Owing to the impact of natural disturbances, allowable cuts have been reduced, which has a direct impact on the supply of wood fibre for forest companies.[22] Brian Fehr, Founder and Chairman of Peak Renewables, stated, “The days of easy access to cheap fibre destined for high-paying stable markets are done.” Finally, some witnesses pointed out that overlap between federal and provincial government policies and regulations is also impeding access to Canada’s forest resources and a stable supply of wood fibre.[23]

Demand and Price Volatility

Fluctuating prices and shifts in demand for certain forest products are affecting forest companies’ liquidity, posing a major barrier to maintaining or expanding forest industry operations. Prices and demand for basic forest products such as lumber can fluctuate cyclically or change in the aftermath of major market disruptions, such as those that have occurred during the COVID‑19 pandemic. Some businesses have lost revenue and need liquidity to continue operating and meet their financial obligations.[24] Tina Rasmussen, Corporate Development and Administration Officer at Meadow Lake Tribal Council Industrial Investments, explained that Indigenous economic development corporations that redistribute revenues in their communities have been hit especially hard. Indigenous forest companies are seeing lower revenues, which could affect communities’ ability to provide the services these revenues fund, such as education or health care. Jean‑François Samray suggested that one way to help forest companies bear the additional costs and make up for the lack of liquidity would be to set up a program that enables them to obtain bank letters of guarantee while ensuring the program complies with international trade rules.[25]

Access to Communication Technologies

The modernization of forestry operations and facilities is being hindered by a lack of access to the latest communication technologies in forestry communities. Derek Nighbor stated that high-speed internet is vital “for doing day-to-day work in some of these more rural and remote communities but also for advancing drone technology and accelerating some of the innovation in forestry.” To enable forest companies working in remote areas to make their operations more efficient and automate their machinery, communication technologies need to be improved so that digital data can be transferred more quickly and reliably.[26]

The Canadian Context and Support Programs

In Canada, the production and management of forest resources fall mainly under the jurisdiction of the provinces and territories, which are responsible for making and enforcing most forest-related legislation, including regulatory regimes.[27] Federal jurisdiction is limited and covers forests on federal lands, such as national parks, and land reserved for Indigenous people.[28] However, some federal laws and international agreements apply to forests nationwide, including those governing research on protecting, managing and developing forest resources, species at risk and migratory birds.[29]

At the federal level, Natural Resources Canada and the Canadian Forest Service provide forest policy and research support. The Canadian Forest Service has a carbon modelling team that assesses how much carbon Canada’s managed forests sequester.[30] The committee learned that Natural Resources Canada’s initiatives to support Canada’s forestry sector and promote innovation were renewed in the 2019 federal budget with an additional $250 million in funding over three years, starting in 2020–2021. These initiatives include the Forest Innovation Program, the Investments in Forest Industry Transformation program, the Expanding Market Opportunities program and the Indigenous Forestry Initiative. Further initiatives were launched to protect Canada’s forests from insect pests, including the National Forest Pest Strategy, which is designed to support research and monitoring activities and reduce the damage to Canada’s forests.[31] The federal government also committed in the 2020 Speech from the Throne to plant an additional 2 billion trees over the next 10 years.[32]

Lastly, the department responsible for international trade, Global Affairs Canada, helps manage trade in forest products, including the softwood lumber dispute between Canada and the U.S. and the development of new export markets for those products. For example, the Minister of Small Business, Export Promotion and International Trade, Mary Ng, told the committee that her department is “strengthening” existing trade agreements while pursuing new ones as part of its Export Diversification Strategy. The goal is to diversify Canada’s markets and consequently boost its exports by 50% by 2025. In 2019, funding of $290 million over five years was announced to increase the support for Canadian exporters—including those in the forestry sector—provided by the CanExport program and the Trade Commissioner Service.[33] In addition, the federal government developed an Action Plan on Softwood Lumber with $867 million in funding to mitigate the impacts of the countervailing and anti-dumping duties imposed by the U.S. in 2017.

The COVID-19 Pandemic’s Impact on the Forestry Sector

The COVID‑19 pandemic has disrupted the global economy. The disease and the public health measures taken to prevent its spread have dislocated supply chains and reduced global demand. Witnesses explained that the pandemic has worsened the economic challenges that Canada’s forest industry was already facing and continues to affect the sector significantly.

The climate of uncertainty created by the pandemic slowed operations in the forestry sector, affecting more than 130 mills, through either closures or production curtailments, and impacting 19,700 workers in Canada.[34] Forest companies faced a drop in demand, fluctuating prices for some resources and liquidity constraints.[35] The committee found that forest companies had to be nimble to keep operating and protect their workers’ safety. Tina Rasmussen explained to the committee that her business “continued … [its] operations through the implementation of stringent safety protocols and by allowing for flexible staffing in the face of unplanned absences that may arise due to worker shortages complicated by COVID.”

After the short period of uncertainty that led to reduced operations at the start of the pandemic, the forestry sector quickly returned to full capacity, as governments deemed that it provided essential goods for Canadian society, such as sanitary products, food packaging, medical and personal protective equipment, and construction materials.[36] The sector recovered rapidly, supported by increased demand for certain forest products, including in the residential construction sector. The Minister of Natural Resources and Forestry of Ontario, John Yakabuski, remarked, “Healthy demand levels meant that forest companies were able to overcome the initial lag very quickly, pushing themselves towards full capacity despite the operating challenges presented by the pandemic.” Minister Ng provided an update on the current situation, telling the committee that “the Canadian softwood lumber industry has almost fully recovered from the early challenges of COVID‑19. Nearly all the 98 sawmills that closed last year as a result of the pandemic have restarted operations, restoring 96% of the more than 12,000 jobs affected.”

The COVID‑19 pandemic has also affected the pulp and paper industry, which was already facing persistent challenges. Maxime Cossette, Vice-President of Fiber, Biomaterials and Sustainability at Kruger, informed the committee that some Kruger plants had to close because the pandemic has accelerated the decline in demand for newsprint and printing paper. With the significant rise in telework since the start of the pandemic, demand for some paper types shrank by 40%. Prior to the pandemic, demand for these products was declining at a rate of 15% per year.

On the other hand, the increased need for essential products such as sanitary paper products and protective masks led the industry to open new facilities to meet the demand. The committee heard that some businesses were able to adapt their operations to focus on products that met the public’s immediate needs during the COVID‑19 pandemic. For example, FPInnovations reassigned its personnel and accelerated its research into developing a biodegradable wood-based protective mask, work made possible by a collaboration with Natural Resources Canada.[37]

To support businesses and Canadian workers during the pandemic, the federal government implemented a range of measures, including the Canada Emergency Wage Subsidy and work-sharing initiatives. It also provided up to $30 million in financial assistance for the forestry sector to help small and medium-sized businesses cover the costs of new COVID‑19-related health and safety measures, to be delivered by the provinces. Beth MacNeil, Assistant Deputy Minister of the Canadian Forest Service at Natural Resources Canada, told the committee that these measures helped protect the jobs and safety of workers and local communities. She pointed out, for example, that this funding saved the tree-planting season: 600 million trees were planted in 2020 despite a cost increase of up to 20%. Moreover, not a single worker contracted COVID‑19 during the season.

Provincial governments also took various steps to help the forestry sector cope with the COVID‑19 pandemic, including supplying personal protective equipment, reimbursing infrastructure expenses more quickly, deferring stumpage fee payments to the government and increasing annual allowable cuts.[38]

The committee heard considerable evidence regarding the future of the forestry sector and its important role in Canada’s economic recovery and in meeting its GHG emissions targets. For example, Brian Fehr, Founder and Chairman of Peak Renewables, made the following comments:

The forest sector will be an important part of Canada’s post-COVID economic recovery, an important driver of innovation, an important partner in helping governments meet their clean energy and emissions target and a living example of how to do all of that in partnership with …[I]ndigenous peoples and rural communities.

The Environmental Benefits of Wood: Promoting a Renewable and Environmentally Sustainable Resource

A number of witnesses who contributed to this study reported that Canada’s forests and its use of wood constitute a natural way of reducing GHG emissions.[39] As depicted in Figure 3, trees absorb carbon dioxide (CO2) as they grow. This carbon is stored in the wood until it is burned or decomposes. Wood can therefore be a carbon-neutral resource, depending on how it is harvested and the products it is used to make.

Figure 3—Carbon Cycle of Forest Products

Source: Figure prepared by the Library of Parliament using additional data provided in writing by the FPAC to the Standing Committee on Natural Resources.

Werner Kurz, Senior Research Scientist at the Canadian Forest Service, explained that the sector’s carbon balance varies depending on how the wood is used. Two factors must be considered:

- the CO2 retention time, meaning how long carbon is retained in a wood product. For example, using wood as a construction material stores carbon for longer than using it for sanitary paper, as it has a longer lifespan; and

- the displacement factor (or substitution benefits), which is the quantity of emissions avoided by using wood products rather than products that emit more CO2, such as concrete and steel in the construction sector or fossil fuels and petrochemical products.[40]

The Canadian Forest Service estimates that Canada’s managed forests contain 220 tonnes of CO2 per hectare. One cubic metre of wood contains the equivalent of about one tonne of CO2. This stock of carbon has accumulated over thousands of years in the forest soil and over hundreds of years in its biomass.[41] Natural Resources Canada asserted that “[t]he focus on managed forests is vital, because having a clear understanding of direct human impacts can inform how we develop approaches to reduce carbon emissions and increase carbon sequestered by our forests.”[42]

Natural Disturbances: A Threat to Forests’ Carbon Balance

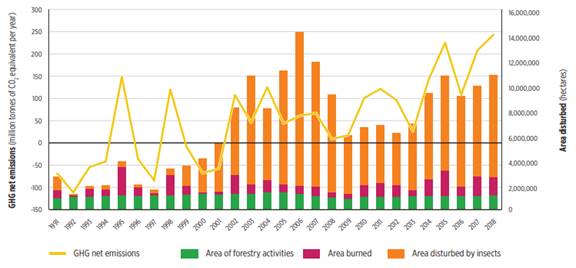

Depending on the year, Canada’s forests may either emit more carbon than they absorb or, conversely, absorb more than they emit.[43] These carbon fluxes in forests vary with natural changes (forest fires, insect pests, tree growth and decay) and forest management practices (deforestation and reforestation).

Figure 4—Net carbon emissions in Canada's managed forests: All areas, 1991–2018

Source: Natural Resources Canada, The State of Canada’s Forests—Annual Report 2020.

A number of witnesses corroborated the data in Canada’s National Inventory Report 1990–2018, which show, for example, that harvesting, reforestation and wood-based materials absorbed 14 million tonnes of CO2 equivalent (Mt CO2 eq.) in 2018.[44] As shown in Figure 4, managed forests also generated about 250 Mt CO2 eq. in 2018 because of natural disturbances, including the forest fires in British Columbia (B.C.).[45] The committee heard that measures to prevent infestations of insect pests and forest fires, afforestation (planting trees to create new forests) and increased urban forest cover can help limit GHG emissions from Canada’s forests.

Measures to Prevent Insect Infestations and Forest Fires

A number of witnesses stated that preventing and limiting insect pest infestations can keep Canada’s forests healthy.[46] Devin Dreeshen, Minister of Agriculture and Forestry of Alberta, explained that his province is making a serious effort to contain the spread of the mountain pine beetle. To date, Alberta has spent $560 million to combat this insect pest and protect pine forests worth an estimated $11 billion. Minister Dreeshen also pointed out that the federal government has provided Alberta with $60 million over three years to help it fight the infestation and ensure it does not move eastward.[47] Witnesses recognized that timely interventions to prevent the spread of insect pests are not always possible.[48] In such cases, the damaged wood should be harvested as soon as possible to obtain the best value from it, but this is not a systematic practice.

In addition, preventing forest fires helps preserve Canada’s forests and protect communities located in forested areas.[49] Witnesses referenced the FireSmart initiative, a partnership between firefighting agencies and Parks Canada to protect communities and the forests around them from forest fires.[50] Some witnesses also mentioned that forest biodiversity can help prevent forest fires.[51] Kathy Lewis, of the University of Northern British Columbia, explained to the committee that, “around communities, there’s a great incentive to try to include birch and aspen in the forest as a way to protect the communities,” as these species resist fire better than conifers. She said that, if these trees are added to commercially harvested coniferous forests, it will be important to find markets for them. Diane Nicholls, Chief Forester of British Columbia, added that “Biodiversity of species for wildfire mitigation is also a best practice. B.C. is working on ensuring that there is a mosaic of forests across our lands that enables forest resilience to natural disturbances and emulates balance for all ecosystem values.”

Increased Forest Cover

Multiple witnesses reported that planting trees helps reduce GHG emissions and pointed to the federal government’s plan to plant 2 billion trees over 10 years. Beth MacNeil explained that these trees will supplement existing reforestation programs. The Fall Economic Statement 2020 stated that this plan could cost up to $3.16 billion over 10 years, starting in 2021–2022. Forest companies are already required to replant one tree for every tree they cut down (between 500 million and 600 million trees are planted every year in Canada).[52]

Estimates by Claude Villeneuve, Professor at the Université du Québec à Chicoutimi, indicate that

It's important to keep in mind that if two billion trees were planted in Canada today, the maximum uptake of CO2 would occur between 2040 and 2080. Assuming a maximum uptake of two kilograms for the least productive species to 10 kilograms for the most productive species, planting two billion trees would at best remove a maximum of 5 to 10 million tonnes of CO2 per year from the atmosphere, which would be equivalent to the total emissions from Canada's aluminum smelters.

Questions were raised about whether Canada has the capacity to increase seedling production to meet this demand and whether tree-planting jobs can be filled without taking labour directly from forest companies.[53] Some witnesses argued that major investments are needed to increase nurseries’ production capacity.[54] Kathy Abusow, President and Chief Executive Officer of the Sustainable Forestry Initiative, pointed out that the project to plant 2 billion trees could offer youth valuable opportunities to gain experience in forestry sector jobs. While the plan is still under development, Natural Resources Canada has already estimated that a land area equal to twice the size of Prince Edward Island will be needed to plant these new trees. In addition, communities willing to accept the additional trees must be found.[55] Other witnesses underscored the need to fund research to ensure that a variety of tree species are planted in the “right place,” taking into account the health and adaptability of these trees in a changing climate.[56]

Urban forests also play an important role in Canadians’ quality of life. Danielle St‑Aubin, Chief Executive Officer of Tree Canada, explained that urban trees provide a number of environmental benefits (they reduce the heat island effect, manage stormwater, prevent soil erosion and provide food and shelter for birds), economic benefits (they increase tourism, boost property values and lower heating and cooling costs) and health benefits (they enhance air quality, improve people’s mood and emotional state and motivate people to go outside and stay active). Some witnesses said that the federal government’s plan to plant 2 billion trees is an opportunity to make Canada’s urban areas greener.[57]

Forest Management in Canada: Promoting Sustainable and Inclusive Management

Witnesses described Canada as a world leader in sustainable forest management.[58] Kate Lindsay, Senior Vice-President of Sustainability and Environmental Partnerships at the FPAC, said that while “Just 11% of the world’s forests are third party certified; 35% of those certified forests are here in Canada.”[59] Some witnesses agreed that forestry certification is a comparative advantage for Canadian forest products in a context where international customers are seeking more transparency and taking environmental, social and governance factors into account in their business decisions.[60]

Other key aspects of Canada’s forestry sector are its relations with Indigenous peoples and their contribution to sustainable forest management.[61] As Kathy Abusow described it, many Indigenous communities have a “geographic alignment” and “traditional ties” with Canada’s forests. As noted above, about 12,000 Indigenous people were directly employed in the forestry sector in 2016. Some witnesses pointed out that these employment opportunities, along with training, have created expertise in these communities. That said, Indigenous involvement in Canada’s forestry sector is increasingly diverse and may include acquiring forest tenure, creating business partnerships and developing Indigenous businesses in the forestry sector or related sectors such as trucking.[62] Derek Orr, appearing as an individual, and Tina Rasmussen explained that these initiatives are fostering economic development in Indigenous communities, as the revenues generated by these businesses are usually injected into the community.

Some witnesses mentioned that the federal Indigenous Forestry Initiative (IFI) has helped develop the forest economy in a number of Indigenous communities.[63] For instance, Rick Connors, President and Chief Executive Officer of Gitxsan Development Corporation, explained that the IFI enabled the Gitxsan Nation to purchase a delivery truck to ship the wood pellets it produces to residential and commercial customers from B.C. all the way to Houston, Texas. Beth MacNeil reported that the IFI received 112 proposals in its last call for proposals and that $74.5 million will be distributed once the project evaluations are complete. According to Tina Rasmussen, “The grant program, although helpful, is more about doing studies and gaining better understanding of land use and a lot less about building infrastructure and creating economic development.” She recommended increasing funding for the program and making its rules more flexible.

Finding a Balance Between Developing and Conserving Forest Resources

While the witnesses agreed that Canada has high forestry standards, this study also revealed different approaches to striking a balance between developing and conserving the country’s forest resources.

William Lahey, President and Vice-Chancellor of the University of King’s College, appearing as an individual, shared with the committee the findings of a report he prepared on forest management in Nova Scotia. In the report, he recommended taking a three-pronged approach to forest management—the “ecological triad”—that creates forest areas dedicated purely to conservation, areas allocated to intensive forestry and areas where forestry can occur, but only in a way that replicates the natural disturbances caused by wind, pests, etc. Mr. Lahey acknowledged that optimal forest management practices can vary by region. He suggested that the federal government conduct more research into the country’s various forest ecosystems to determine the impacts that forest practices are having on Canadian forests and better understand their resilience to climate change.

Kathy Lewis also mentioned that

Recent research from B.C. has shown that when the economic price of carbon emissions and sinks is combined with timber prices, traditional clear-cuts flip from being the most economical to the least economical harvest practices. As we work towards meeting our Paris Agreement targets, the benefits of promoting the retention of intact forests, as well as wider adoption of partial harvesting practices, must be more fully considered.

Florence Daviet, Director of the National Forest Program at the Canadian Parks and Wilderness Society, noted the following: “By its very nature, industrial forestry activity has associated greenhouse gas emission and biodiversity impacts.” Her organization wants to reduce the impacts of forest development by leaving more to nature, including by protecting 30% of Canada’s lands and waters by 2030, recognizing the non-timber value of forests and adopting forest management practices that increase the rotation ages of trees being harvested.

However, some witnesses asserted that access to forest resources is increasingly restricted by federal and provincial regulations and conservation measures.[64] Alain Paradis, General Manager of the Coopérative forestière de Petit Paris, reported, “Over the past decade, the volume of timber harvested [in Quebec] has dropped by at least 10 million cubic metres annually” because of conservation policies.

Uncertainty surrounding access to wood fibre could also discourage investment in the forestry sector. Susan Yurkovich, President and Chief Executive Officer of the British Columbia Council of Forest Industries, explained:

Secure access to fibre at a reasonable cost is the single biggest factor that can help attract new investment and contribute to economic recovery. That’s why we think that, just like parks and protected areas, we should decide on the size of the working forest and then lock it in. Once we’ve done that, we need to explore innovative ways to manage the forest resource.

In addition, witnesses suggested to the committee that better regulatory coordination between the federal and provincial governments to avoid overlap would result in more predictable access to Canada’s forest resources.[65] In a context where access to wood fibre is more constrained, some witnesses underlined the need to make better use of the wood that is harvested.[66]

Innovation in the Forestry Sector: Developing a Circular Forest Bioeconomy that Makes Better Use of Wood Fibre and Wood Products

“Nature-based climate solutions are not just about planting trees but also about increasing the use of wood and the circular bioeconomy.”

The forestry sector is adapting to the structural changes and challenges it is facing, in part by offering alternatives to higher-carbon-intensity products and diversifying the range of products derived from forest biomass. A number of witnesses stated that making better use of wood fibre and creating a “circular forest bioeconomy” are critical to the prosperity of Canada’s forest industry.[67] This production cycle involves processing forest resources into complementary products until they can no longer be used or they are turned into fuels for bioenergy production. More efficient use of these resources is achieved by utilizing the by‑products of forest industry manufacturing processes (also known as forest residues), which are otherwise considered waste. Value is added not only by processing wood more efficiently, but also by making “next-generation” forest products: bioproducts.[68]

“What is the bioeconomy? To put it simply, it’s creating an economy based on biology. For us, in the forest industry, it’s about how we use trees, how we use the forest to create a more active economy.”

Currently, given a lack of viable commercial markets, some tree biomass is burned on the cut site or left behind. This forest waste, also known as slash, consists mainly of the branches and tops of trees and pieces of broken wood. Werner Kurz explained that

When we refer to slash burning, what we're talking about are the branches, the tops and broken pieces of wood that stay behind. I would estimate that, depending on the area in which we harvest, it will be between 5% and 25% of the carbon in the above‑ground biomass that is not removed from the site. The remainder goes into the harvested wood product sector, and depending on what we produce from it, we must discount the bark. The carbon in the bark is often used as hog fuel or other energy source. Depending on the product, 40% to 50% ends up in long-lived wood products and the remainder often goes into pulp or bioenergy.

Therefore, according to Diane Nicholls, Chief Forester of British Columbia, a large amount of fibre is available “that can be used in the production of higher-value products such as bioplastics, biomaterials and biochemicals that utilize fibre, such as treetops, branches and harvest residuals that currently are not being utilized.”

The committee heard about multiple innovative projects in the forestry sector that could result in increased use of wood fibre, both in more traditional industries, such as construction, and in innovative ones, such as bioproducts.

Increasing the Use of Wood Products in the Construction Sector

The use of wood products in the construction sector is not limited to lumber and wood panels; it also includes an array of value-added products such as cross-laminated wood panels, columns and beams, and insulation made from residual wood fibres. The structural strength, seismic performance and fire resistance of these wood products are comparable with those of traditional construction materials such as concrete and steel.[69]

Demand for certain products, including cross-laminated timber and mass timber, has increased. Jeff Bromley told the committee that some businesses are having trouble finding enough labour to meet this demand. Based on forecasts Natural Resources Canada made in a recent study on value-added wood and engineered wood, Derek Nighbor pointed out that Canada could increase production of these products from $4.4 billion per year to $6.4 billion annually by 2030.

The committee learned that using wood products in the construction sector offers three main environmental benefits:

- 1) The wood used in construction products, such as mass timber and wood fibre insulation, can sequester carbon over the long term, depending on the lifespan of the building.[70]

- 2) Using wood as a structural material can to some extent replace other, more carbon-intensive materials such as concrete and steel.[71]

- 3) Wood structures can be built more quickly than those constructed with traditional materials owing to prefabrication processes. This was the case with Brock Commons, an 18‑storey wood building at the University of British Columbia that was built in 70 days, four times faster than a conventional building.[72]

During this study, witnesses suggested various ways of increasing the use of wood in the construction sector:

- Change the National Building Code to allow the construction of tall wood buildings. The National Building Code currently authorizes the construction of mass timber buildings of up to six storeys in height, but multiple witnesses believe that allowing 12‑storey wood buildings at the national level—as is already the case in some provinces and municipalities—could boost domestic demand for mass timber products.[73] Jeff Waring, Director General of the Trade, Economics and Industry Branch at Natural Resources Canada, told the committee that his department is currently working with the National Research Council of Canada to develop and implement these new standards. Frédéric Verreault, Executive Director of Corporate Development at Chantiers Chibougamau, argued that the National Building Code should be oriented around the desired fire resistance and earthquake safety objectives. In a brief to the committee, the Canadian Home Builders’ Association (CHBA) stated that the cost of insurance for wood frame buildings can be 10 times that for a concrete building. The CHBA called this a challenge that must be overcome if Canada wishes to increase the number of wood structures.[74]

- Promote the use of wood products in construction to stimulate the demand. Some witnesses emphasized that mass timber products and bioproducts such as wood fibre insulation need to be promoted as construction materials.[75] Ken Kalesnikoff said that some developers remain wary of using mass timber because it is a relatively unfamiliar product compared with concrete and steel.[76] Frédéric Verreault told the committee that $1.1 million in funding provided by Natural Resources Canada a few years prior played a key role in launching the Origine project, a 13‑storey mass timber condominium building in Quebec City, which is now a showcase for the industry’s potential. As Mr. Verreault explained, “It was a small amount at the time, but it made a big difference.” Chantiers Chibougamau has now “delivered tens of millions of dollars’ worth of solid wood structures for medium- and high‑rise buildings.” Minister Yakabuski, noted that Natural Resources Canada’s Green Construction through Wood Program—now closed to funding applications—promoted the adoption and marketing of tall wood buildings and other wood structures such as bridges. He believes that this kind of program helps the industry grow and create jobs, and he encouraged the federal government to renew its investments in such programs in the future.

- Develop a public procurement policy that favours the use of wood products. Some witnesses recommended that the federal government establish a public procurement policy that gives preference to mass timber materials in government buildings.[77] For instance, Susan Yurkovich pointed to B.C., where an initiative gives priority to mass timber as a construction material.[78] In her view, stimulating demand would, in turn, boost production. Frédéric Verreault highlighted the example of the City of Paris, which “announced that all the infrastructure needed for the 2024 Paris Olympic Games will be made of solid wood.”

- Develop a building performance standard for carbon emissions. To increase the demand for wood products in construction, Don Roberts, President and Chief Executive Officer of Nawitka Capital Advisors Ltd., recommended that “policy-makers recognize the carbon emissions produced by construction and the carbon stored in the built environment.” Sylvain Labbé, Chief Executive Officer of the Quebec Wood Export Bureau, agreed that a carbon emissions performance-based system with mandatory targets would give the construction industry the flexibility it needs to achieve the targets and would very likely favour wood products, with their proven GHG emissions mitigation benefits.

Diversifying and Increasing the Supply of Bioproducts

The committee learned of a number of innovations in the forest bioproducts (biomaterials and bioenergy) sector that could make better use of wood fibre, lead to new value-added, low-carbon-intensity products, and protect or create good jobs. The witnesses referred to a variety of biomaterials: biochemicals for the cosmetics industry, paint emulsifiers, bamboo fabric for clothing, personal protective equipment (biodegradable masks and medical wear), bioplastics (bottles made from bio-waste and food packaging), carbon fibres (or nanofibres) used in the automobile and aviation industries, adhesives for making wood panels, insulating foams, concrete biofilaments, biopolymers, biocomposites and bio-coke (charcoal used in steelmaking).[79]

In addition to the manufacturing of biomaterials, forest biomass can also be used to produce bioenergy. Various energy products can be made from it: solid products (wood pellets for heating and electricity production), liquid products (biocrude oil) and gas products (biogas or renewable natural gas). Some witnesses stated that making these products offers environmental and economic benefits. They result in optimal use of forest residues (or low-quality biomass) that would otherwise be unused or burned, local production of renewable energy that can replace higher-emission energy sources and the creation of jobs necessary for producing and using these products in remote regions.[80] The committee also heard that technical improvements have made the performance of bioenergy comparable to that of fossil fuels.[81]

While Canada’s bioenergy sector is growing, witnesses pointed out that it is not yet mature. Its markets are abroad, and local production is mainly for export. For example, the largest markets for wood pellets used for heating are currently in Asia (particularly Japan) and northern Europe.[82] Some witnesses commented that Canadian producers should be able to take advantage of growing global demand for wood pellets, but that developing the domestic market could also improve commercial opportunities and reduce Canada’s GHG emissions.[83] This development could involve converting heating systems in remote regions or Indigenous communities that are off the grid—and depend on diesel fuel or other higher-emission energy sources—or in heavy industries, such as cement plants and steel mills.[84]

In Canada, several provinces are looking to leverage the circular forest bioeconomy to diversify the sector’s operations and provide a range of innovative products. The committee learned that efforts are underway to identify potential opportunities for wood fibre created by the bioeconomy.[85] Witnesses made the following suggestions to make the most of innovative uses of wood and value-added products:

-

Develop a value chain for processing forest resources into bioproducts in Canada. According to Natural Resources Canada, “Advanced bio‑based products are expected to make up 50% of consumer products by 2050.”[86] Some witnesses explained that, to take advantage of this demand, domestic processing capacity for bioproduct production must be increased in order to expand markets, attract investments and create jobs in Canada.[87] Derek Nighbor raised the following problem: while Canada has the capacity to produce the reinforced pulp used to make personal protective equipment—for example, at the Harmac mill in B.C.—it exports much of its output, which then returns in the form of value‑added products. Diane Nicholls said that, in B.C., no company has yet entered into the manufacturing of biomaterials, bioplastics or biochemicals because there is no place to send the fibre.

Likewise, the life-cycle analysis conducted by the Consortium de recherche et innovations en bioprocédés industriels au Québec (CRIBIQ) revealed many benefits associated with bioproducts, such as reducing waste and GHG emissions and “limiting the relocation of high value-added products, since most of the jobs associated with bioproducts must be close to biosources.”[88] According to Emmanuelle Rancourt, “The forest biomass industry can also help strengthen the forest industry by creating permanent jobs that remain in the regions thanks to the supply chain, from harvesting and transportation to processing.”

-

Create incentives to support the commercialization of bioproducts. The committee heard about numerous ideas for bioproducts that exist in the laboratory; unfortunately, the weak link in the value chain for these products is integrating them into a commercial business that would enable large-scale production.[89] To address this problem and take advantage of these new possibilities, Diane Nicholls suggested that the federal government “continue supporting research and development so that Canada can become a leader in bioeconomy innovations” and “develop a cross-Canada approach for commercialization of new product production that will attract entrants and support the creation of the circular forest economy sector.” Ms. Nicholls pointed out that Scandinavian countries have been successful in this regard because of government programs to support the commercialization of bioproducts. In her view, incentives for commercialization such as loans and grants could be considered.[90]

Roger Bernier, Microbiologist and Agronomist at the CRIBIQ, suggested that government assistance could take the form of “special tax credits … for the commercialization of bioproducts to make this commercialization much more competitive,” as it is the case in multiple U.S. states. Ken Kalesnikoff underlined that federal programs to transform the forest industry should specifically target the value-added secondary industry. He also remarked that small industry players have trouble obtaining this funding because they lack the necessary resources to put together project proposals.[91]

Beth MacNeil noted that Natural Resources Canada is working to reorient its programs toward the bioeconomy, including the Investments in Forest Industry Transformation program, and to promote the use of various fibres and value-added product manufacturing.

Develop markets for low-carbon products. Some witnesses suggested that the federal government implement a low-carbon-intensity product procurement policy to increase demand for bioproducts. Diane Nicholls said that proposals should be developed to “establish demand by the markets for greener-based solutions for their products.” She explained that this would not mean “trading one industry with another,” but simply taking into account the environmental benefits and possibilities of forest products in procurement policies. As Jean‑François Samray noted, a federal strategic procurement program that emphasizes innovation and value-added products would “provide an opportunity for start-up companies to get their first contract with the federal government, and to prove that they can meet this challenge.”

The committee also heard that demand for bioproducts could be increased if Canadian consumers were better informed about the new options the forestry sector offers.[92] Roger Bernier proposed that Canada consider a bioproduct certification, similar to the American BioPreferred certification, that would lead to labelling that informs consumers about a product’s composition (bio-sourced materials versus materials derived from petrochemicals). This certification could include mandatory purchasing requirements for federal agencies and their contractors.

-

Encourage the conversion of energy systems to low-GHG-emission systems. Fossil fuels such as fuel oil and diesel are still used for residential heating or industrial electricity production in many regions of Canada. In some cases, these fuels could be replaced by forest biomass and thus contribute to reducing Canada’s GHG emissions. John Arsenault informed the committee that, for every tonne of biomass that replaces a fossil fuel, GHG emissions decline by about a tonne. A number of witnesses stated that the main barrier to using biomass to generate energy is the high investment cost.[93] In this regard, Emmanuelle Rancourt suggested that increased government support could speed up the replacement of high-carbon-intensity heating systems with biomass systems.

-

Enhance workforce training to include new wood product uses. A skilled labour force is vital to the success of the new possibilities afforded by the forest bioeconomy. However, as Kathy Lewis noted, there is a “lack of training programs for architects, engineers and especially the construction workers who are able to work with these engineered wood products.” Some witnesses agreed that university education should be available to ensure the construction sector is familiar with wood products.[94] According to Frédéric Verreault, aside from some specialized academic programs such as the graduate program in wood engineering at the Université du Québec à Chicoutimi, no engineering faculty currently specializes in wood construction.

To take advantage of the career opportunities in the sector, including those for workers in remote regions, Indigenous people and youth, Kathy Abusow suggested taking a collaborative approach that emphasizes educational pathways, skills development and work experiences. Roger Bernier said that a “national program should be put in place to facilitate the recruitment, in our university research centres or in government laboratories, of scientific researchers from large private chemical or biotechnology companies that specialize in the industrial conversion of bioresources into high value-added products.” Lastly, some witnesses noted that the bioproduct and petrochemical industries use similar processes and their workers have comparable expertise, therefore opportunities for knowledge transfer may be possible.[95]

During this study, a number of witnesses discussed the impact the Clean Fuel Regulations, currently being developed by Environment and Climate Change Canada, could have on Canada’s forestry sector.[96] The draft regulations would enable suppliers of liquid fossil fuels to utilize forest biomass to make low-carbon-intensity fuels.[97]

To qualify as a clean fuel, forest biomass could come from secondary forest residues or clearing activities not related to harvesting (e.g., wood damaged by insects or road maintenance). The Clean Fuel Regulations would also allow other sources of forest biomass to be used, so long as they are harvested according to a forest management plan that is evaluated by a verification body and meets a series of environmental criteria, including water, soil and biodiversity requirements. Some witnesses see in this standard a way of making better use of some forest by-products, including sawmill residues.[98] However, in a brief to the committee, the Composite Panel Association argued that wood by-products that can be used in high-value-added manufacturing should not serve as fuels. Other witnesses expressed concerns about the federal government’s implementation of the above-mentioned forest management requirements. They stated that forest management is a provincial responsibility and that the provinces already have high environmental standards.[99]

In light of the testimony heard during this study, value-added products such as next-generation bioproducts (biomaterials and bioenergy) are a potential solution for the forest industry, which is looking to diversify while reducing GHG emissions. Nevertheless, as Jeff Bromley pointed out, the solid wood sector will remain important, in part because it is necessary for the production of numerous by-products. It is therefore necessary to take into account their respective contributions and recognize the challenges they face in order to develop strategies to improve their commercial performance. The United Nations data cited by Minister Yakabuski indicate that demand for wood products will increase by 30% by 2030. This figure includes conventional products, but also innovative uses of wood that meet the needs of markets looking for substitutes for higher-carbon-intensity products.

Trade in Forest Products: Dispute Settlement and Market Diversification

The issue of the trade dispute with the U.S. over softwood lumber is critical to Canada’s forest industry, especially in a context of economic recovery. Multiple witnesses stated that the countervailing and anti-dumping duties imposed by the U.S. on certain Canadian softwood lumber producers are unjustified and unfair.[100] Furthermore, Minister Ng, and the Global Affairs Canada officials explained that most of the legal challenges Canada brought under the North American Free Trade Agreement and before the World Trade Organization (WTO) have been supportive of Canada’s position on this issue.

Arun Alexander, Director General of the North America Trade Policy Bureau, reported that the U.S. government takes the position that the stumpage rate system used in some Canadian provinces to authorize logging on public lands is below market value for softwood lumber.

Colin Barker, Director of the Softwood Lumber Division, explained to the committee that B.C. and Quebec reformed their auction systems in part to counter American claims that these provinces subsidize softwood lumber through overly low stumpage rates. However, he said that, in the case of B.C., the U.S. government delayed its review of the reforms made to the provincial forestry system. In its most recent tariff review process, the U.S. Department of Commerce reduced the average countervailing and anti‑dumping duties on softwood lumber by more than half. While this was good news for Canadian softwood lumber producers, multiple witnesses nonetheless believe that implementing a new lumber trade deal would provide greater certainty for the industry.[101]

Minister Ng emphasized that the Government of Canada would like to negotiate a softwood lumber agreement with the U.S. that is in the interest of both countries. She believes the arrival of the new administration of President Joe Biden is an opportunity to renew trade relations with the U.S. Global Affairs Canada officials further stated that the new U.S. administration seems open to improving the trade dispute settlement process. The officials said that, to achieve this goal, the first step is resolving the quorum issue at the WTO Appellate Body in order to resume hearing cases.[102] Because of this issue, a challenge Canada brought regarding softwood lumber is currently stalled. In August 2020, the WTO had ruled that American tariffs on Canadian lumber exports did not comply with U.S. obligations under WTO trade rules. Arun Alexander explained to the committee that Minister Ng is leading the Ottawa Group, a subgroup of WTO members looking at potential reforms to the organization to improve its structure and operating rules.

In addition to a settlement of the softwood lumber dispute with the U.S., the committee heard about other avenues for improving Canada’s trading opportunities in the forestry sector:

- Diversify export markets to reduce dependence on the U.S. market. Witnesses told the committee that, in recent years, the forest industry has been working with the federal and provincial governments to diversify its export markets. Beth MacNeil said that Natural Resources Canada’s Expanding Market Opportunities program, which focuses on Asian markets such as China, India and Japan, has helped diversify export markets for Canadian wood products over the past few years. Because of their geographic position, the Western provinces—particularly B.C.—have an advantage that enables them to export to these markets more easily. Ontario, Quebec and the Maritime provinces export more of their products to the U.S., but opportunities also exist in European markets. As Minister Ng noted, Canada’s trade agreements with Asia (the Comprehensive and Progressive Agreement for Trans-Pacific Partnership) and Europe (the Comprehensive Economic and Trade Agreement Between Canada and the European Union) offer interesting trading opportunities for Canadian wood products. Moreover, Canada is the only G7 country to have a trade agreement with each of the other six member countries.

- Increase exports of value-added products. The committee noted that value-added products such as engineered wood are not subject to U.S. tariffs, offering an opportunity to the forestry sector.[103] Sylvain Labbé remarked that developing value-added products and exporting them could be a viable strategy given growing demand for these products in the U.S. and around the world. He also added that “The market development program needs to be enhanced to develop the value-added products industry in terms of exports. Currently, the focus is on overseas exports, and it is imperative that this program be redesigned to increase the export of value-added products.”[104]

- Promote Canadian wood products abroad. The committee was informed of efforts to promote Canadian wood products in other countries. Beth MacNeil explained that the Expanding Market Opportunities program includes an educational component to inform architects and engineers in countries that import Canadian wood about the options for building with mass timber and the environmentally sustainable nature of these products. Minister Ng stated that the Trade Commissioner Service is showcasing Canadian wood products internationally. She also mentioned the CanExport program, which offers financial support to small and medium-sized Canadian businesses looking to boost their presence in global markets.

- Expand the domestic market. To reduce the sector’s dependence on foreign markets, some witnesses suggested increasing the use of wood in the Canadian market.[105] As Don Roberts explained, the growing interest in mass timber buildings provides an opportunity to significantly boost domestic demand for Canadian wood products.

Conclusion

Given the testimony heard during this study, the committee is of the view that the Canadian forestry sector has the assets it needs to remain a key economic sector in Canada. Moreover, the sector is critical to many rural and Indigenous communities, which depend on the forest industry and the thousands of jobs it creates.

To support its growth and secure its future, the forestry sector is diversifying and developing or commercializing numerous innovative bioproducts. The optimal use of wood fibre in these new products and the increased adoption of mass timber in the construction sector are also helping capture and store more carbon and reduce GHG emissions. As well, it is important for Canada to diversify its export markets for wood products and to find a long-term resolution to the current softwood lumber trade dispute with the U.S. in order to ensure the stability of the sector.

Well-managed forest ecosystems and increased forest cover—including in cities—are also part of the solution to climate change. Together with rural and Indigenous communities located near forested areas, Canada’s forestry sector is well-positioned to offer a broad range of forest products derived from sustainably managed forests to customers both in Canada and abroad.

[1] Natural Resources Canada [NRCan], The State of Canada’s Forests—Annual Report 2020; NRCan, Follow-up questions for the House of Commons Standing Committee on Natural Resources [RNNR].

[2] RNNR, 2nd Session, 43rd Parliament, [Evidence]: Jeff Bromley (Chair, Wood Council, United Steelworkers); Forest Products Association of Canada [FPAC], FPAC’s response following the meeting of 3 November 2020.

[3] NRCan, The State of Canada’s Forests—Annual Report 2020. Note: This percentage was calculated by dividing the number of jobs held by Indigenous people by the total number of jobs in the forest industry in 2016, using data from Census 2016.

[4] RNNR, Evidence: Beth MacNeil (Assistant Deputy Minister, Canadian Forest Service, NRCan).

[6] Note that this classification of primary and secondary manufacturing products may differ from the evidence heard and government reports consulted.

[7] NRCan defines forest biomass as “the material contained in the trees of a forest, including all their components (roots, branches, leaves, etc.).”

[8] RNNR, Evidence: Kathy Abusow (President and Chief Executive Officer, Sustainable Forestry Initiative); Werner Kurz (Senior Research Scientist, Canadian Forest Service, NRCan); Kathy Lewis (Acting Vice-President, Research, University of Northern British Columbia, As an individual); NRCan, Follow-up question for RNNR.

[9] RNNR, Evidence : Florence Daviet (Director, National Forest Program, Canadian Parks and Wilderness Society [CPWS]).

[10] RNNR, Evidence: Roger Laurent Bernier (Microbiologist and Agronomist, Consortium de recherche et innovations en bioprocédés industriels au Québec [CRIBIQ]); Daviet (CPWS); MacNeil (NRCan).

[11] NRCan, The State of Canada’s Forests—Annual Report 2020, p. 58.

[12] RNNR, Evidence: Kate Lindsay (Senior Vice-President, Sustainability and Environmental Partnerships, FPAC); Derek Nighbor, (President and Chief Executive Officer, FPAC).

[13] RNNR, Evidence: MacNeil (NRCan); Don Roberts (President and Chief Executive Officer, Nawitka Capital Advisors Ltd.).

[16] RNNR, Evidence: Maxime Cossette (Vice-President, Fiber, Biomaterials and Sustainability, Kruger Inc.); Jean‑François Samray (President and Chief Executive Officer, Quebec Forest Industry Council [QFIC]).

[21] Diane Nicholls, Study of the Standing Committee on Natural Resources on economic recovery in the forestry sector, Request for additional information, 9 December 2020.

[22] RNNR, Evidence: Nighbor (FPAC); Stéphane Renou (President and Chief Executive Officer, FPInnovations).

[23] RNNR, Evidence: Nighbor (FPAC); Susan Yurkovich (President and Chief Executive Officer, British Columbia Council of Forest Industries [BCCFI]).

[27] Parliament delegated forest management powers to Yukon and the Northwest Territories in devolution agreements and their implementation Acts. Very little logging occurs in Nunavut: Canadian Council of Forest Ministers, “Canada’s Legal Forest Products,” Sustainable Forest Management in Canada, 2018.

[28] In these cases, this jurisdiction stems from two provisions of the Constitution Act, 1867: section 91(1A), which provides for federal jurisdiction over federal public property, and section 91(24), which grants the federal government jurisdiction over “Indians, and lands reserved for the Indians.”

[29] NRCan, Canada’s forest laws.

[31] RNNR, Evidence: MacNeil (NRCan); Hon. Devin Dreeshen (Minister of Agriculture and Forestry, Government of Alberta).

[33] RNNR, Evidence: Hon. Mary Ng (Minister of Small Business, Export Promotion and International Trade, Global Affairs Canada); Global Affairs Canada, Minister Carr announces investments to help Canadians access new markets, new customers, new jobs, 9 April 2019.

[35] RNNR, Evidence: MacNeil (NRCan); Samray (QFIC); Hon. John Yakabuski (Minister of Natural Resources and Forestry, Government of Ontario).

[39] RNNR, Evidence: Maxime Cossette (Kruger Inc.); Jason Krips (President and Chief Executive Officer, Alberta Forest Products Association [AFPA]); Kurz (NRCan); Sylvain Labbé (Chief Executive Officer, Quebec Wood Export Bureau); Kathy Lewis (Acting Vice-President, Research, University of Northern British Columbia, As an individual); MacNeil (NRCan); Diane Nicholls (Assistant Deputy Minister and Chief Forester, Ministry of Forests, Lands, Natural Resource Operations and Rural Development of British Columbia); Samray (QFIC); Frédéric Verreault (Executive Director, Corporate Development, Chantiers Chibougamau); Claude Villeneuve (Professor, Université du Québec à Chicoutimi [UQAC]); Yurkovich (BCCFI).

[40] RNNR, Evidence : Arsenault (Vision Biomasse Québec); Kurz (NRCan); Villeneuve (UQAC).

[42] Additional information provided in writing by NRCan to the Standing Committee on Natural Resources.

[43] RNNR, Evidence: Abusow (Sustainable Forestry Initiative); Lewis (As an individual); Kurz (NRCan); additional data provided in writing by the FPAC to the Standing Committee on Natural Resources.

[44] Environment and Climate Change Canada, National Inventory Report 1990–2018: Greenhouse Gas Sources and Sinks in Canada, Part I, 2020, p. 48. Lindsay (FPAC), MacNeil (NRCan), Nighbor (FPAC) and Kurz (NRCan) confirmed these data. However, The State of Canada’s Forests—Annual Report 2020, published by Natural Resources Canada in January 2021, instead stated that carbon absorption in 2018 was 8 Mt of CO2 eq.

[45] Because they are caused by natural disturbances, these emissions are not counted in Canada’s total greenhouse gas emissions (719 Mt CO2 eq. in 2018).

[46] RNNR, Evidence: Dreeshen (Government of Alberta); Ken Kalesnikoff (Chief Executive Officer, Kalesnikoff Lumber Co. Ltd. [Kalesnikoff Lumber]); Krips (AFPA); Nicholls (Ministry of Forests of British Columbia); Yakabuski (Government of Ontario).

[47] NRCan, Protecting Canada’s Forests From the Mountain Pine Beetle, 8 October 2020. The $60 million provided to the Government of Alberta must go toward forest management and research work to mitigate the impacts of the mountain pine beetle.

[49] RNNR, Evidence: Brian Baarda (Chief Executive Officer, Peak Renewables); Dreeshen (Government of Alberta); Lewis (As an individual); Nicholls (Ministry of Forests of British Columbia).

[51] RNNR, Evidence: Lewis (As an individual); Nicholls (Ministry of Forests of British Columbia); Danielle St‑Aubin (Chief Executive Officer, Tree Canada).

[53] RNNR, Evidence: Mike Beck (Operations Manager, Capacity Forest Management Ltd.); Villeneuve (UQAC).

[55] RNNR, Evidence: Derek Orr (As an individual); Villeneuve (UQAC).

[56] RNNR, Evidence: William Lahey (President and Vice-Chancellor, University of King's College, As an individual); Nicholls (Ministry of Forests of British Columbia); Villeneuve (UQAC).

[57] RNNR, Evidence: Abusow (Sustainable Forestry Initiative); Adrina Bardekjian (Manager, Urban Forestry Programs and Research Development, Tree Canada); St-Aubin (Tree Canada).

[58] RNNR, Evidence: Dreeshen (Government of Alberta); MacNeil (NRCan); Nicholls (Ministry of Forests of British Columbia); Yakabuski (Government of Ontario).

[59] Three certification systems currently exist in Canada: those of the Canadian Standards Association, the Forest Stewardship Council and the Sustainable Forestry Initiative.

[61] RNNR, Evidence: Abusow (Sustainable Forestry Initiative); Tina Rasmussen (Corporate Development and Administration Officer, Meadow Lake Tribal Council Industrial Investments [MLTC]); Yurkovich (BCCFI).

[62] RNNR, Evidence: Beck (Capacity Forest Management Ltd.); Orr (As an individual); Rasmussen (MLTC).

[63] RNNR, Evidence: Rick Connors (President and Chief Executive Officer, Gitxsan Development Corporation); Rasmussen (MLTC).

[64] RNNR, Evidence: Krips (AFPA); Nighbor (FPAC); Orr (As an individual); Alain Paradis (General Manager, Coopérative forestière de Petit Paris); Yurkovich (BCCFI).

[66] RNNR, Evidence: Bernier (CRIBIQ); Connors (Gitxsan Development Corporation); MacNeil (NRCan); Orr (As an individual); Renou (FPInnovations); Roberts (Nawitka Capital Advisors Ltd.).

[67] RNNR, Evidence: Abusow (Sustainable Forestry Initiative); Mohammed Benyagoub (President and Chief Executive Officer, CRIBIQ); Bernier (CRIBIQ); Lewis (As an individual); MacNeil (NRCan); Renou (FPInnovations); Roberts (Nawitka Capital Advisors Ltd.).

[68] RNNR, Evidence: Benyagoub (CRIBIQ); Lewis (As an individual); Nicholls (Ministry of Forests of British Columbia); Emmanuelle Rancourt (Coordinator and Co-spokesperson, Vision Biomasse Québec).

[69] RNNR, Evidence: Lewis (As an individual); Verreault (Chantiers Chibougamau); RNNR, Brief: Canadian Home Builders’ Association (CHBA), Economic Recovery in the Forestry Sector and Its Intersection with Residential Construction, 11 January 2021.

[70] RNNR, Evidence: Patrick Dallain (General Manager, SEREX); Kurz (NRCan); Lewis (As an individual); MacNeil (NRCan); Roberts (Nawitka Capital Advisors Ltd.); Villeneuve (UQAC).

[71] RNNR, Evidence: Bromley (Wood Council, United Steelworkers); Daviet (CPWS); Kurz (NRCan); Lewis (As an individual); Verreault (Chantiers Chibougamau); Villeneuve (UQAC).

[72] RNNR, Evidence: Bromley (United Steelworkers); Ng (Government of Canada); Nighbor (FPAC); Samray (QFIC).

[73] RNNR, Evidence: Bromley (United Steelworkers); Krips (AFPA); MacNeil (NRCan); Nicholls (Ministry of Forests of British Columbia); Nighbor (FPAC); Renou (FPInnovations); Samray (QFIC); Verreault (Chantiers Chibougamau); Jeff Waring (Director General, Trade, Economics and Industry Branch, Canadian Forest Service, NRCan); Yakabuski (Government of Ontario).

[74] RNNR, Brief: CHBA, Economic Recovery in the Forestry Sector and Its Intersection with Residential Construction, 11 January 2021.

[75] RNNR, Evidence: Dallain (SEREX); Kalesnikoff (Kalesnikoff Lumber); Lewis (As an individual); Samray (QFIC); Yurkovich (BCCFI).

[76] RNNR, Evidence: Kalesnikoff (Kalesnikoff Lumber); Verreault (Chantiers Chibougamau); Yurkovich (BCCFI).

[77] RNNR, Evidence: Kalesnikoff (Kalesnikoff Lumber); Labbé (Quebec Wood Export Bureau); Renou (FPInnovations); Samray (QFIC); Verreault (Chantiers Chibougamau); Yurkovich (BCCFI).

[78] The initiative that Susan Yurkovich refers to is the Wood First Act, a law that requires all buildings funded by B.C. to give priority to wood as a construction material.

[79] RNNR, Evidence: Benyagoub (CRIBIQ); Dallain (SEREX); Rosaline Kwan (Director General, Trade Sectors, Global Affairs Canada); Lewis (As an individual); MacNeil (NRCan); Nicholls (Ministry of Forests of British Columbia); Renou (FPInnovations); Mohini Mohan Sain (Chief Consultant, GreenNano Technologies Inc.).

[80] RNNR, Evidence: Connors (Gitxsan Development Corporation); Lewis (As an individual); Rancourt (Vision Biomasse Québec); Rasmussen (MLTC); Roberts (Nawitka Capital Advisors Ltd.).

[81] RNNR, Evidence: John Small (Chief Executive Officer and Founder, ERS Fuels Inc.); Yakabuski (Government of Ontario).

[84] RNNR, Evidence: Nicholls (Ministry of Forests of British Columbia); Rancourt (Vision Biomasse Québec); Small (ERS Fuels Inc.).

[87] RNNR, Evidence: Benyagoub (CRIBIQ); Nicholls (Ministry of Forests of British Columbia); Nighbor (FPAC); Rancourt (Vision Biomasse Québec); Renou (FPInnovations).

[93] RNNR, Evidence: Arsenault (Vision Biomasse Québec); Connors (Gitxsan Development Corporation); Rasmussen (MLTC).

[94] RNNR, Evidence: Kalesnikoff (Kalesnikoff Lumber); Verreault (Chantiers Chibougamau).

[96] RNNR, Evidence: Arsenault (Vision Biomasse Québec); Dallain (SEREX); Dreeshen (Government of Alberta); Krips (AFPA); Kurz (NRCan); Nicholls (Ministry of Forests of British Columbia); Roberts (Nawitka Capital Advisors Ltd.); Rancourt (Vision Biomasse Québec); Rasmussen (Meadow Lake Tribal Council Industrial Investments); Yakabuski (Government of Ontario); Composite Panel Association. Note that some witnesses appeared before the committee prior to the publication of the first version of the Clean Fuel Standard in the Canada Gazette, Part I, on 19 December 2020.

[97] The liquid fossil fuels that would be subject to the Clean Fuel Standard are gasoline, diesel, kerosene and light and heavy fuel oils.

[98] RNNR, Evidence: Arsenault (Vision Biomasse Québec); Dallain (SEREX); Roberts (Nawitka Capital Advisors Ltd.); Rancourt (Vision Biomasse Québec).

[99] RNNR, Evidence: Dreeshen (Government of Alberta); Nicholls (Ministry of Forests of British Columbia); Yakabuski (Government of Ontario).

[100] RNNR, Evidence: Bromley (United Steelworkers); Scott Doherty (Executive Assistant to the National President, Unifor); Ng (Government of Canada); Samray (QFIC); Yakabuski (Government of Ontario); Yurkovich (BCCFI); RNNR, Brief: CHBA, Economic Recovery in the Forestry Sector and Its Intersection with Residential Construction, 11 January 2021.

[101] RNNR, Evidence: Bromley (United Steelworkers); Doherty (Unifor); Kalesnikoff (Kalesnikoff Lumber); Labbé (Quebec Wood Export Bureau); Ng (Government of Canada); Nighbor (FPAC); Rasmussen (MLTC); Samray (QFIC); Yakabuski (Government of Ontario); Yurkovich (BCCFI); RNNR, Brief: CHBA, Economic Recovery in the Forestry Sector and Its Intersection with Residential Construction, 11 January 2021.

[102] Michael Owen (Acting General Counsel and Executive Director, Softwood Lumber Litigation Division, Global Affairs Canada).