FOPO Committee Report

If you have any questions or comments regarding the accessibility of this publication, please contact us at accessible@parl.gc.ca.

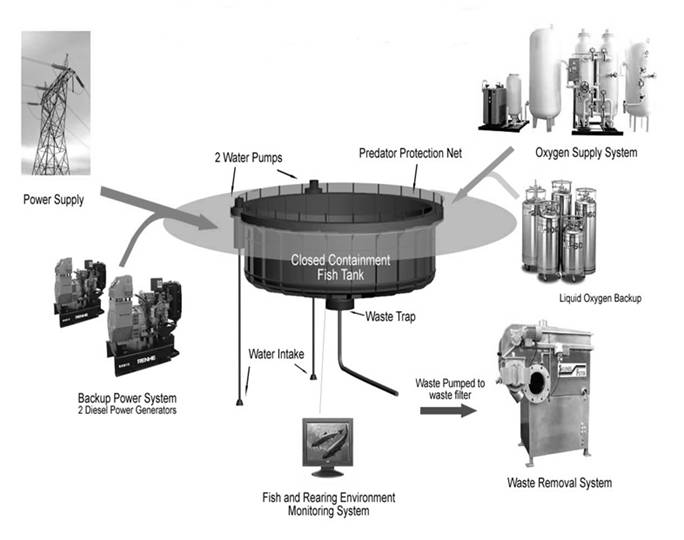

CLOSED CONTAINMENT SALMON AQUACULTURE REPORTINTRODUCTIONOn October 18, 2011, the Committee agreed to undertake a study on closed containment salmon aquaculture. The Committee has a history of interest in aquaculture, the latest example being in the 40th Parliament. At that time, a decision was made to begin an in-depth examination of the aquaculture industry across the country. This effort began in the Pacific region, but the study was incomplete at time of the election. The Committee agreed to consider evidence received and testimony heard from that study insofar as it was relevant to closed containment aquaculture. The Committee convened 18 meetings between October 2011 and March 2012 to study the matter, hearing submissions and testimony from representatives of Fisheries and Oceans Canada (DFO), scientists and academics, the open-net pen aquaculture industry, the closed containment aquaculture industry, consultants, Aboriginal groups, environmental organizations, coastal communities, retailers, and recreational and commercial fishers (a complete list is attached to this report). The Committee members would like to express their sincere thanks to the witnesses who appeared before them to share their knowledge, experience and recommendations over the course of this study. These contributions were invaluable in the preparation of the following report, and the Committee members acknowledge those involved with gratitude. The Committee traveled to Washington D.C. and West Virginia in March 2012 to hear from representatives of the National Oceanic and Atmospheric Administration and the United States Department of Agriculture with respect to American initiatives and priorities in aquaculture regulation, funding, and research and development. In West Virginia, the Committee visited one of the foremost closed containment aquaculture research facilities in the world in order to speak with the scientists and engineers engaged in this cutting edge research. The Committee is pleased to present its report, in which it makes recommendations to the federal government. These recommendations are based on the testimony of witnesses as well as the Committee's own analysis of the issues. BACKGROUNDA. Previous Committee StudiesThe Committee last studied the issue of aquaculture between 1999 and 2003, which culminated in the April 2003 report: The Federal Role of Aquaculture in Canada.[1] In that 83-page report only one recommendation pertained to closed containment.[2] As a result of increased scrutiny on the environmental impacts of the aquaculture industry, closed containment technologies have become a major focus of aquaculture research and development. The fact that this report focuses entirely on closed containment aquaculture indicates how much the dialogue has changed over the last decade. B. Salmon Aquaculture in CanadaAquaculture accounts for 14% of total fish and seafood production in Canada by landed volume, or 35% by value.[3] Canadian aquaculture production includes several species of salmon, trout, mussels, and oysters. Salmon farming is by far the largest industry accounting for 63% by volume, or 75% by value of total Canadian production, the vast majority of which is Atlantic salmon. In 2010, Canada raised 101,385 tonnes of farmed salmon, for a total (farm gate) value of $690.9 million. The same year, Canada exported almost 80,000 tonnes of salmon, 98% of which was Atlantic salmon.[4] The salmon aquaculture industry expanded dramatically over the course of the 1980s and 1990s. The Canadian industry experienced some declines during the early to mid-2000s due largely to disease outbreaks and global market factors.[5] While initially made up of many smaller companies, the salmon aquaculture industry has undergone considerable consolidation and vertical integration in Canada, with the vast majority of production now raised by just four companies in each of British Columbia and New Brunswick,[6] and three companies in Nova Scotia.[7] There are approximately 130 sites (80 active at any given time)[8] in British Columbia, 90 sites in New Brunswick[9] and 15 in Nova Scotia.[10] Newfoundland and Labrador had 12 sites as of 2010, but is experiencing significant growth in this sector.[11] Globally, Canada produced about 7% of the world's farmed salmon in 2009, ranking fourth in terms of salmon aquaculture production, behind only Norway, the UK and Chile.[12] In 2010, Canada exported approximately 78,000 tonnes of farmed salmon to the US (approximately 77% of our total production) for approximately $525 million.[13] Canadian farmed salmon was also exported to Japan, France, Taiwan and other countries to a lesser degree. There has been no significant growth in salmon aquaculture production in Canada over the past decade, with 2010 production volumes still slightly less than they were in 2001.[14] This is attributable to a variety of factors, including a decline in world prices for Atlantic salmon, a moratorium on new salmon farm licences in British Columbia, and new farm siting and environmental management requirements.[15] Industry representatives, however, have told the Committee that they believe the time is ripe for expansion again, as American demand is growing at a rate of 3% to 5% per year.[16] C. Current Salmon Aquaculture Farming PracticesThe vast majority of salmon farmed in Canada and around the world are Atlantic salmon that are raised in open-net pen aquaculture farms in coastal areas in the ocean. Atlantic salmon has become the species of choice for aquaculture producers due to a number of factors, including market demand, relatively rapid growth rates, less aggressive behaviour, and superior disease resistance. In conventional net pen operations, salmon spend about one third of their lives in closed containment systems at a hatchery. When the salmon smolts are approximately 12 cm in length or 100 g (12 to 18 months after hatching), they are transferred to net pens in the ocean, where they stay and grow for an additional 18 to 24 months before being harvested. Atlantic salmon are typically considered to be of harvestable size when they are approximately 4.5 to 6 kg. Salmon aquaculture sites vary in size, but they typically consist of a series of 6 to 24 floating, mesh cage-like structures made of plastic, steel and/or aluminum. Salmon farms are usually located in sheltered bays and fjords where they will be protected from extreme currents and storms, and are anchored to the ocean floor to keep them in place. Farmed salmon are fed dry pellets consisting of fish meal, fish oil and plant proteins, enriched with vitamins, minerals and carotenoids. The fish meal and fish oil are derived from small wild fish such as anchovy, menhaden and capelin, obtained primarily from South America. Much research has been conducted, however, in an effort to reduce the amount of fish meal and fish oil required to produce the feed for farmed salmon. CLOSED CONTAINMENT TECHNOLOGIESClosed containment aquaculture refers to a number of technologies that seek to isolate the rearing environment from the natural environment in order to reduce or eliminate the interactions between the two. Not all types of closed containment systems are entirely separated from the natural environment, and as a result some are more "closed" than others. While a number of different technologies and systems have been designed and piloted over the years, the two most relevant technologies that seem to have emerged for the Canadian salmon farming industry are ocean-based solid-wall containment systems and land-based, recirculating aquaculture systems (RAS). A. Ocean-Based Solid-Wall SystemsOcean-based solid-wall containment systems consist of solid-walled fibre and foam composite tanks ranging in size from 3000 m3 to 10,000 m3 that float at the surface of the water. The water intake allows water to be drawn into the tank from varying depths (which provides for control over water quality and temperature). Supplemental oxygen is pumped into the tank to maintain optimal dissolved oxygen levels. Waste feed and feces are filtered out via a drain at the bottom of the tank and pumped away with the expectation that it could be treated for disposal on land as a fertilizer, while the remainder of the relatively clear water is allowed to overflow over the top of the tank into the surrounding waters. Figure 1: The AgriMarine Closed Containment System[17]

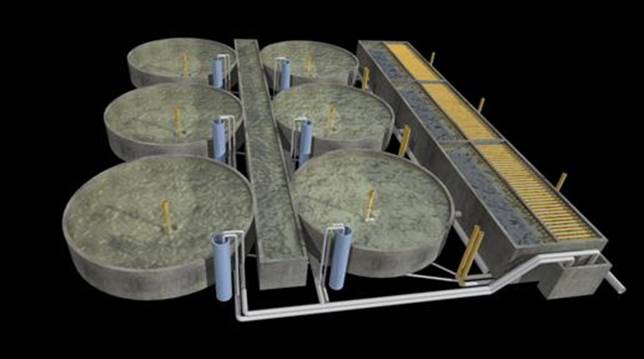

Such systems are not completely closed because the intake water is not treated before entering the tank and water from the tank is released back into the ocean. Nevertheless, the system is successful in removing 90% of settleable wastes, which, in an open-net pen aquaculture system, would otherwise settle to the ocean floor or be dispersed by ocean currents. In addition, due to the solid walls, the system provides for separation of wild and farmed populations and reduces the risk of escapes and predation. As stated by Robert Walker of AgriMarine Industries: Our technology provides what net cage farms cannot. These features allow us to farm in adverse conditions year round and operate well above density levels practical for net cages without causing undue stress to the fish. The solid-wall system also contributes to a healthier surrounding ecosystem… The waste removal process eliminates the undesirable addition of nutrients to local marine ecosystems. With solid-wall containment there's no possibility of interaction between farmed and wild, no fish escapes, no predator interactions.[18] B. Land-based Recirculating Aquaculture Systems (RAS)Land-based RAS use large, circular concrete tanks arranged in modules on land. Because the tanks are land-based, they must be located in proximity to an adequate supply of either groundwater or seawater. Water is pumped into the tank and continually recirculated; water quality is maintained through various means, including mechanical filtration, UV irradiation, CO2 strippers and ozone injection. Solid wastes are drained out the bottom of the tank and removed to a settling basin, and can ultimately be treated to be used as compost or fertilizer. Through this constant recirculation and treatment of water, these systems can reuse 98% of the input water. Figure 2: Land-Based RAS Closed Containment System[19]

Land-based RAS are designed to physically separate fish from the external environment. Because water is treated before entering the tanks and no water is released to the natural environment, there are virtually no vectors for disease, pathogen or parasite transfer between wild and farmed populations. These systems also offer near complete control over water quality, temperature, oxygenation and other parameters, although electricity and technology requirements are necessarily greater. C. Existing Closed Containment AquacultureClosed containment technologies, including RAS, have existed for several decades and are currently available as commercial, off-the-shelf systems from a number of different vendors.[20] Most of these technologies have been developed or refined for the global closed containment aquaculture industry for other species, as well as for the existing closed containment salmon broodstock and hatchery facilities. The Committee learned that closed containment systems are currently used successfully (and profitably) at commercial scale for other species such as tilapia, sturgeon, arctic char, and trout. Target Marine Hatcheries, for example, in Sechelt, BC, raises sturgeon in a land-based RAS facility for the production of both caviar and sturgeon meat. Tilapia is similarly raised in land-based RAS in Ontario, Alberta and BC. Although there are not yet any commercial-scale closed containment systems raising Atlantic salmon anywhere in the world, closed containment technologies already play a significant role in parts of the farm-raised Atlantic salmon growth-cycle, both in Canada and abroad. The Committee heard from Marine Harvest that their salmon spend approximately the first third of their lives in closed containment RAS (up to the point where the smolts are transferred to the net pen sites). In addition, half of their broodstock is raised entirely in a dedicated RAS facility.[21] These practices are now common in the industry in order to exercise greater control over environmental factors and reduce business risk. There are a small and growing number of closed containment aquaculture facilities in British Columbia, Montana and Washington State that are producing Pacific salmon commercially. While Atlantic salmon farms are typically considered to be "commercial-scale" at 1000 tonnes production capacity, Pacific salmon can be raised profitably at the 100 tonnes to 200 tonnes scale. Coho salmon, it was explained to the Committee, provide better opportunities for niche marketing (thereby fetching a higher price per kilogram); but because Atlantic salmon are a global commodity product, significantly larger economies of scale are required in order to be profitable.[22] One of these land-based RAS raising Pacific salmon is Swift Aquaculture, in Agassiz, BC. The farm raises coho salmon in freshwater tanks, and also operates as a multi-trophic aquaculture site, using the nutrient-rich water from the salmon tanks to grow watercress and wasabi, which in turn produces algae to feed crayfish. The coho salmon from this farm is currently sold to high-end restaurants in Vancouver. Plans exist to expand this site to a 1000 tonnes RAS operation. Additionally, as John Holder of JHL Consulting has testified, the farms can be flexibly located as long as the land price is not exorbitant: These farms can be put in urban areas, not necessarily rural ones. They do not have to be near a body of water…We can set up close to the markets, which is going to cut down our transport cost.[23] Coho salmon are also raised by AquaSeed Corporation at their 100 tonnes land-based RAS facility in Washington State, as well as through a joint venture with Teton Fisheries at two 160 tonnes facilities in Montana. These coho are marketed under the brand "SweetSpring Salmon," which supplies Overwaitea Food Group supermarkets in British Columbia and Alberta. D. Atlantic Salmon Commercial-Scale Pilot ProjectsDespite the challenges anticipated in attempting to grow Atlantic salmon in closed containment units at a production cost that will be competitive with global open-net pen salmon aquaculture production, a significant amount of research and a number of pilot projects have already been carried out. While some past pilots have demonstrated that some technologies are not feasible for Atlantic salmon production, there are currently at least three projects at various stages of construction or engineering in Canada that seek to demonstrate the potential to ultimately expand beyond the pilot-scale to full, commercial scale production: the AgriMarine project at Middle Bay, the K'udas project with the 'Namgis First Nation, and Marine Harvest's planned pilot (in cooperation with the Canadian Alliance for Aquaculture Reform) on northern Vancouver Island. AgriMarineAs described above in the section on closed containment technologies, AgriMarine Industries Inc. operates an ocean-based solid-wall containment pilot project near Campbell River, on Vancouver Island. The project, operated in cooperation with the not-for-profit Middle Bay Sustainable Aquaculture Institute has received funding from Sustainable Development Technology Canada (SDTC) and the Gordon and Betty Moore Foundation in order to carry out the initial phases. The first 3000 m3 floating tank was installed in the bay in January 2011 and was stocked initially with chinook salmon fingerlings. While the first harvest was scheduled for late spring or early summer of 2012 a severe wind storm in March 2012 resulted in some structural damage to the demonstration tank and the decision to conduct an early harvest.[24] The three remaining tanks have been redesigned and installation was planned for 2012, which would raise the total annual production of the site to approximately 900 tonnes. According to Robert Walker, the President of AgriMarine Industries Inc., the company is "very close to commercialization."[25] 'Namgis First NationThe K'udas Project is a collaboration between the 'Namgis First Nation and the SOS Marine Conservation Foundation to build a pilot-scale land-based RAS on the Cheslakees Indian Reserve, 5 km south of Port McNeill on Vancouver Island. The project has been designed such that, initially, only one module with an annual production capacity of 260 tonnes to 500 tonnes will be installed. Data collected from pilot operations will then be used to refine the design where necessary and to expand to a full-size, commercial-scale facility with an annual production capacity of 1000 tonnes. The project has been designed with a number of innovative features intended to reduce operating costs and maximize revenues, including heat recovery and heat pump technologies that are estimated to reduce energy costs by a factor of 10. The site is also being designed to eventually accommodate aquaponics, whereby the nutrient-rich effluent water will be used to grow plants in greenhouses. The project has received funding from SDTC, Tides Canada and the Coast Sustainability Trust to assist with the initial $6 to $7 million in capital costs associated with the project. Site clearing work began over the winter of 2011-2012 and construction was to be completed by August 2012. The intention was for the first production cycle of Atlantic salmon to take place between September 2012 and September 2013. Marine HarvestThe Committee heard from Marine Harvest Canada that the company is planning to undertake a pilot project in order to document the actual costs and benefits of commercial scale RAS production, and to contrast the collected information with the figures for conventional net pen production. Marine Harvest engaged the engineering firm Worley Parsons to conduct a site selection survey, prepare an engineering proposal and conduct a life-cycle analysis of the systems. This preparatory work has been completed, and the cost of a 300 tonnes per year pilot on the east coast of Vancouver Island was estimated at $8 million.[26] Partial funding for the project was committed by DFO and SDTC. Although Marine Harvest had intentions to proceed based on these preliminary studies, a reduction in the world market price of salmon resulted in the required $5 million in funding from Marine Harvest's parent company not being approved at this time, and the project was put on hold while alternative funding sources are being sought out or until the market price of salmon improves.[27] POTENTIAL BENEFITS OF CLOSED CONTAINMENT AQUACULTUREThe Committee heard extensive evidence about the potential benefits of closed containment salmon aquaculture. These include the potential for reduced business risks, reduced environmental impacts and improved socio-economic outcomes. A. Reduced Business RiskOpen-net pen aquaculture involves risks because it is exposed to external environmental hazards. As explained by the Canadian Aquaculture Industry Alliance, some of these hazards include: the exposure to diseases or parasites carried by wild fish; water quality or pollution issues; storms; escapes or predation. Losses in Chile due to disease were alluded to a number of times. In Canada, one producer noted their experience with losses due to poor water quality that had affected their outlook on net pen aquaculture: We actually were net cage farmers — we grew chinook salmon on the northwest coast of Vancouver Island for quite a few years — and ended up losing our farms because of several significant losses of fish due to uncontrolled plankton blooms in the area. We wanted to stay in the salmon farming business, but we didn't want to keep losing fish...[28] It was a desire to reduce these business risks that initially prompted aquaculturists to conduct research into closed containment technologies,[29] similar to what they have used for smolts and broodstock production. AgriMarine gave up net pen production entirely and began pursuing closed containment due to a series of large stock losses for the company in the 1990s, and other companies are still investigating the economics. Marine Harvest Norway, for example, signed an agreement with AgriMarine in early 2012 to test AgriMarine's technology to support post-smolt production of fish up to 1 kg with the aim of demonstrating “the economic benefits of the AgriMarine System over conventional net cage systems.”[30] Marine Harvest Canada also has plans to investigate the economics of lengthening the amount of time young salmon are raised in RAS before being transferred to net pens, thereby reducing the amount of time the fish are exposed to the risks of the ocean growing environment, as well as potentially reducing total production times by optimizing the growing conditions.[31] B. Reduced Environmental ImpactsThe Committee heard a great deal of testimony about the impacts of open-net pen salmon farming on wild fish and the environment. Some of the most commonly cited concerns include: